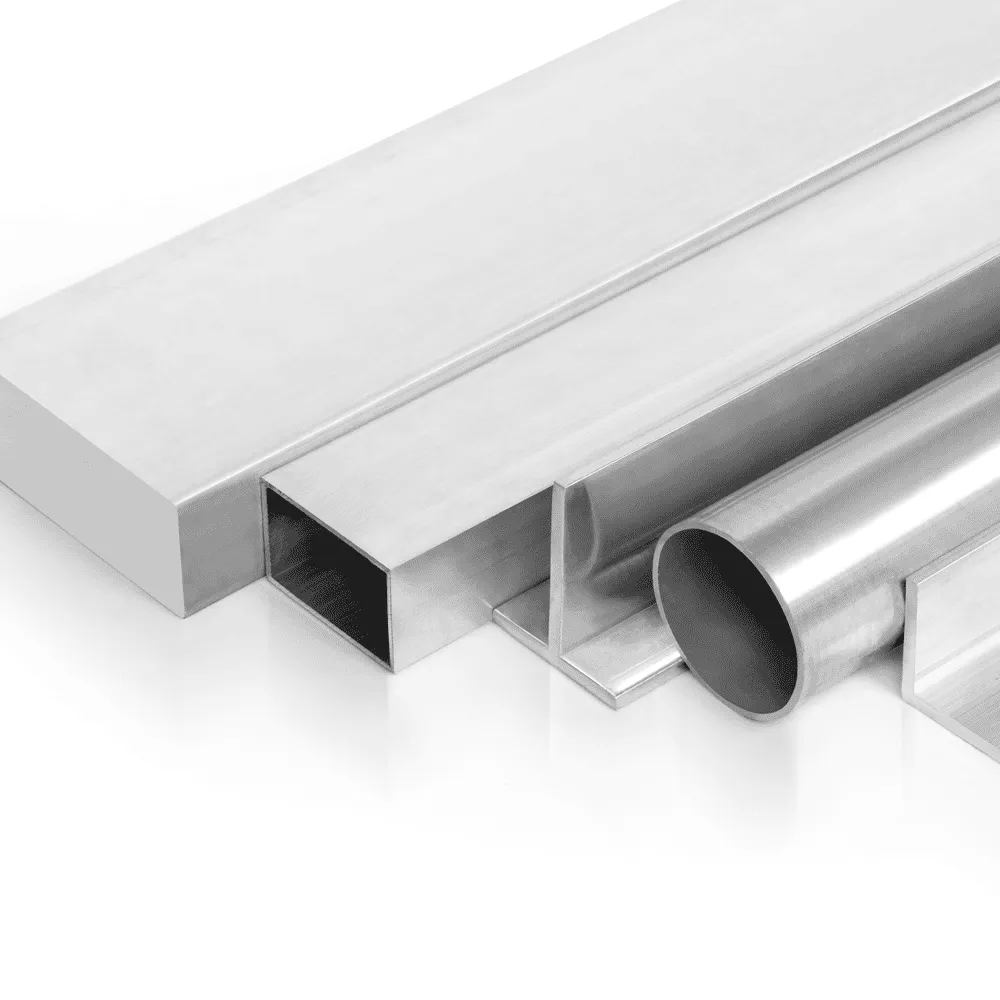

Aluminium extrusions are widely used in shelving, cabinets, and storage frames because they strike the right balance between strength and lightness. But understanding how weight factors into using aluminium extrusions is crucial if you’re looking to build something that’s not only functional but also long-lasting and safe.

Load Capacity vs. Frame Weight

One of the first things to assess when planning a storage system is the relationship between the frame’s weight and the load it needs to carry. This is where aluminium extrusions shine.

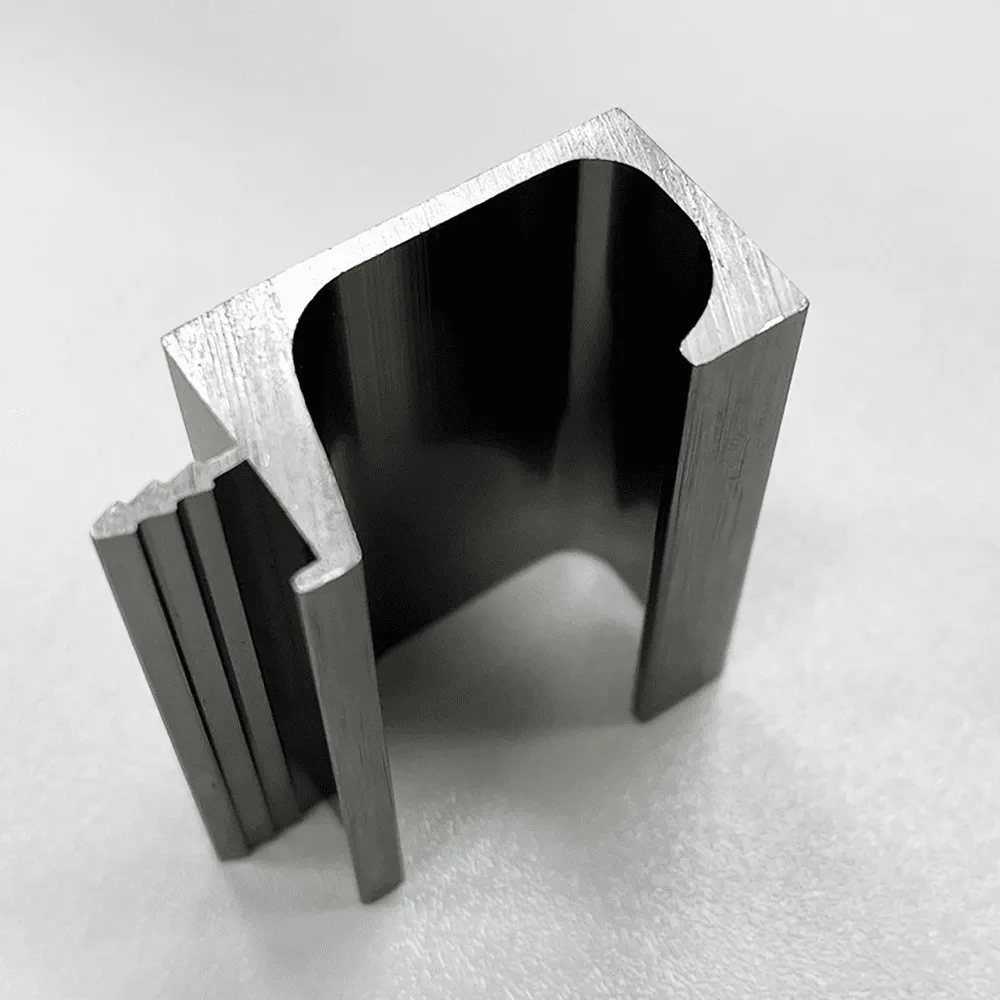

Thanks to their structural design, extrusions can be engineered to handle heavy loads without adding unnecessary bulk. Hollow profiles and reinforced ribs can increase strength while keeping the overall weight low. That means you can install multi-tier shelving units that feel sturdy but are still light enough to shift around if needed.

This is especially helpful in domestic or office settings where the floors or walls aren’t designed to handle excessive weight. You get strength where it counts—without stressing the structure of the room.

Wall Mounting? Weight Becomes Even More Critical

If your storage solution involves mounting to a wall, the weight of the frame becomes even more important. Too much weight on plasterboard or unsupported studs can lead to serious safety hazards. Aluminium’s lightweight profile helps minimise this risk.

Many wall-mounted cabinets and shelves now rely on aluminium framing because it keeps the unit’s total weight low. This makes it easier to secure with standard wall fixings and reduces the likelihood of damage over time. In contrast, using heavier materials like solid timber or steel might require reinforcement behind the wall, adding time and cost to the project.

Floor-Standing Units: Stability and Weight Distribution

For floor-standing storage units, weight affects stability and how the load is distributed across the floor. Lighter aluminium frames don’t put as much strain on the flooring, which is important for second-storey installations or areas with vinyl and laminate finishes.

That said, the lightness of aluminium does raise questions about tipping and stability—especially for taller units. To counterbalance this, you can use wider base profiles, floor brackets, or even weight down the bottom shelves. The flexibility of aluminium extrusions allows you to easily incorporate these adjustments into the design without much hassle.

Modular Systems: Lightweight for the Win

Modular storage has exploded in popularity—especially in garages, offices, and retail environments. These setups often need to be customisable and easy to move around.

Aluminium extrusions are ideal here because their lightweight nature makes them a breeze to handle, assemble, disassemble, and reconfigure. Need to add another tier? Slide in a new profile. Want to change the layout? No need to worry about lugging heavy frames across the room. And because of aluminium’s high strength-to-weight ratio, you don’t have to compromise on how much the unit can hold.

For example, many adjustable shelf brackets, cross beams, and side rails are made from slimline aluminium profiles that hold a surprising amount of weight without adding bulk to the system.

Comparing to Other Materials

Let’s talk comparisons. Timber, steel, and plastic are other common materials for indoor storage.

- Timber looks good and has a traditional feel but is heavier and less flexible. Over time, wood can warp or degrade—especially in humid indoor areas like laundries or bathrooms.

- Steel is incredibly strong but often too heavy for residential or light commercial applications unless you need extreme durability.

- Plastic is light but can be flimsy and has limited weight-bearing capacity.

Aluminium sits comfortably in the middle. It’s strong enough to hold its own in heavy-duty applications, but light enough to install without special lifting equipment or structural support.

Custom Storage? Think About Load Types

The type of load your storage needs to handle will influence which aluminium extrusion profiles you should use. Static loads (e.g., books or tools that don’t move much) can be supported with slimmer profiles. But if you’re dealing with dynamic loads—like drawers that slide or shelves that get rearranged—then consider thicker or reinforced extrusions.

This is where talking to your supplier matters. Many aluminium suppliers offer custom-cut profiles with specific load ratings. You can get corner joints, T-slots, and channels designed to fit together seamlessly and bear the intended weight without the guesswork.

Finishing Touches that Affect Weight

Another thing to factor in is the finishing materials. The aluminium frame might be lightweight, but if you’re adding thick glass panels, hardwood doors, or heavy inserts, the total weight increases. This can undo the benefits of a lightweight frame if not planned properly.

That’s why many people opt for aluminium composite panels or lightweight MDF inserts in their shelving and cabinets. These materials keep the overall weight down while still offering an attractive, durable finish.

Final Thoughts

Weight considerations are a big deal when planning indoor storage, and aluminium extrusions offer the ideal mix of strength, flexibility, and lightness. Whether you’re mounting units to a wall, placing them on a floating floor, or building a fully modular system, aluminium lets you manage the total weight of the setup without compromising on performance or aesthetics.