Retrofit control work usually starts with the same problem: the air conditioning technically runs, but it never behaves the same way twice. One day it is freezing at reception and warm in the back offices, the next day it flips. Staff keep changing setpoints, timers get overridden, and everyone loses confidence in the system.

A PAC controller install can be a clean way to bring consistency back, especially when you want repeatable sequences, clearer fault visibility, and a control standard that can be applied across multiple units. The difference between a smooth retrofit and a painful one comes down to process, staging, and commissioning discipline, not just the controller itself.

When a Retrofit Makes More Sense Than a Full Replacement

A full plant replacement is not always required to get better outcomes. If the mechanical equipment is serviceable and the biggest issues are control behaviour, a retrofit can deliver stability faster and at a lower disruption level.

Common signs a retrofit is the right move include:

- The unit is mechanically sound, but comfort is inconsistent across zones

- The system short cycles, hunts, or overshoots setpoints regularly

- Schedules are unreliable, or overrides are unmanaged

- Faults are hard to diagnose because there is limited trending or poor alarms

- Small changes cause big, unpredictable impacts

- Past “quick fixes” have stacked up and nobody trusts the current logic

If the equipment is near end-of-life, has chronic refrigerant leaks, or is undersized for current use, control improvements alone will not solve the core issue. The best retrofit projects are honest about what controls can fix and what they cannot.

Outcomes to Lock in Before You Talk Hardware

A PAC controller is a tool, not the outcome. Start by defining the performance you want, then work backwards into the installation and commissioning plan.

A clear outcomes brief often includes:

- Comfort targets by zone and time of day (including warm-up and pull-down expectations)

- Stability targets (how tightly temperature is maintained, and how aggressively it responds)

- Airflow expectations (minimum ventilation, night purge logic, outside air strategies where relevant)

- After-hours operation rules (who can override, for how long, and what gets logged)

- Fault response expectations (what triggers alerts, who gets notified, and what the operator can do)

- Maintainability outcomes (labelling, documentation, spares, and access levels)

When these outcomes are written down, the retrofit stops being “install a new controller” and becomes “deliver consistent control behaviour”.

Site Survey: What to Confirm Before You Touch a Panel

Retrofits go sideways when the site survey is treated as a quick look. A strong survey identifies what exists, what is missing, what has been modified, and what must stay live during the changeover.

Start with a survey that covers the control chain end to end, from sensors to actuators to the plant itself:

- Unit types and configurations (AHUs, packaged units, split systems, multi-splits, chilled water interfaces)

- Existing control points (temperature sensors, pressure sensors, CO2 sensors, airflow switches, frost protection)

- Outputs and actuators (valves, dampers, fan speeds, compressor staging, VSD interfaces)

- Safety and permissives (smoke control interfaces where applicable, condensate switches, high pressure, low temp)

- Power and isolation points (what can be shut down, when, and by whom)

- Panel condition (space, heat, ingress risk, labelling quality, wiring quality)

- Access constraints (operating hours, ceiling access rules, restricted areas)

You are not trying to document every wire in one visit, but you are trying to prevent the classic surprises, like “this sensor is shared between two units” or “that damper actuator is actually disconnected”.

Choosing a PAC Controller for Retrofit Work

A PAC controller is often selected when you need flexible programming, consistent logic across multiple systems, and enough headroom for trending, alarming, and future expansion. The controller choice should reflect the reality of the site, including who will support it later.

Key selection considerations to put on the table early include:

- I/O needs now and later (including spare capacity for future sensors or zoning)

- Communications requirements (BMS integration, protocol needs, remote monitoring expectations)

- Programming and support (ease of fault-finding, availability of local support, internal capability)

- Environmental suitability (plant room heat, dust, moisture, and enclosure requirements)

- Standardisation strategy (one platform across multiple units reduces long-term variability)

If the proposal calls out a PAC controller, it should also describe how the programming will be standardised and documented. That is what turns a single upgrade into a repeatable improvement program.

Panel Retrofit Planning That Minimises Downtime

Occupied sites do not forgive long shutdowns, so the panel plan has to be about speed, predictability, and rollback. A clean retrofit usually involves building and preparing as much as possible before the actual cutover window.

A practical plan includes:

- Pre-labelling and pre-terminating where possible to reduce time on the night

- A clear isolation plan (what is shut down, what stays live, and what gets verified before restart)

- A staged cutover sequence (one unit, one zone, or one system at a time)

- A rollback plan (what triggers it, and how you revert quickly)

Even if the building can tolerate an after-hours shutdown, you still want the work to be calm and methodical. Fast does not mean rushed, it means prepared.

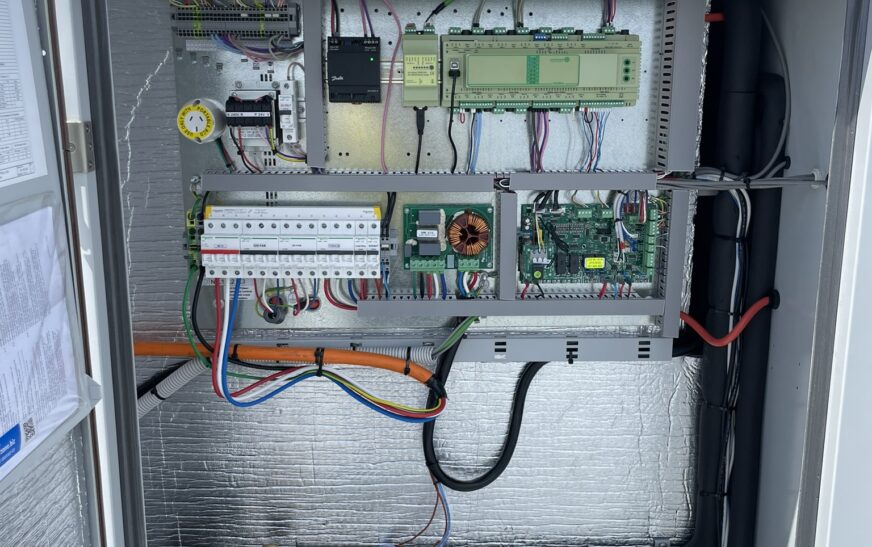

Installation Standards That Reduce Callbacks

Retrofit work gets judged by how it looks and how it behaves under stress. A neat, well-labelled installation reduces future troubleshooting time and improves confidence for everyone who touches it later.

A good standard typically covers:

- Clear device labelling that matches documentation and the points list

- Proper cable management and segregation (control, power, communications)

- Reliable terminations and consistent wire identifiers

- Spare capacity and serviceable layouts, not “packed to the lid”

- Environmental protection for plant rooms (dust, moisture, heat)

Material choices also matter in harsh areas. In some sites, aluminium backplates or aluminium cable management components are used for durability and corrosion resistance, provided bonding and installation details are handled correctly. The goal is long-life practicality, not a fancy finish.

Control Sequences That Deliver Consistency, Not Just Operation

Consistency is usually lost in the edges, like startup transitions, demand changes, and competing priorities. A retrofit is an opportunity to define clear sequences that behave the same way every day.

A solid baseline sequence design often includes:

- Start and stop logic that avoids short cycling and rapid restarts

- Clear setpoint strategy, including limits and deadbands to reduce hunting

- Warm-up and pull-down behaviour that avoids overshoot

- Fan control strategy that matches occupancy and ventilation needs

- Economiser or outside air control that avoids unnecessary humidity or temperature swings where relevant

- Lockout rules (for example, compressor lockout during certain conditions)

- Manual override rules with time limits and clear logging

This is where a PAC controller can shine, because you can implement a consistent library of proven sequences rather than one-off logic that only the original programmer understands.

Key Takeaways

A PAC controller install can be a strong retrofit pathway to consistent air conditioning control, but the controller is only one part of the result. The real value comes from good survey discipline, clean installation standards, repeatable sequences, and commissioning that proves stability over time.