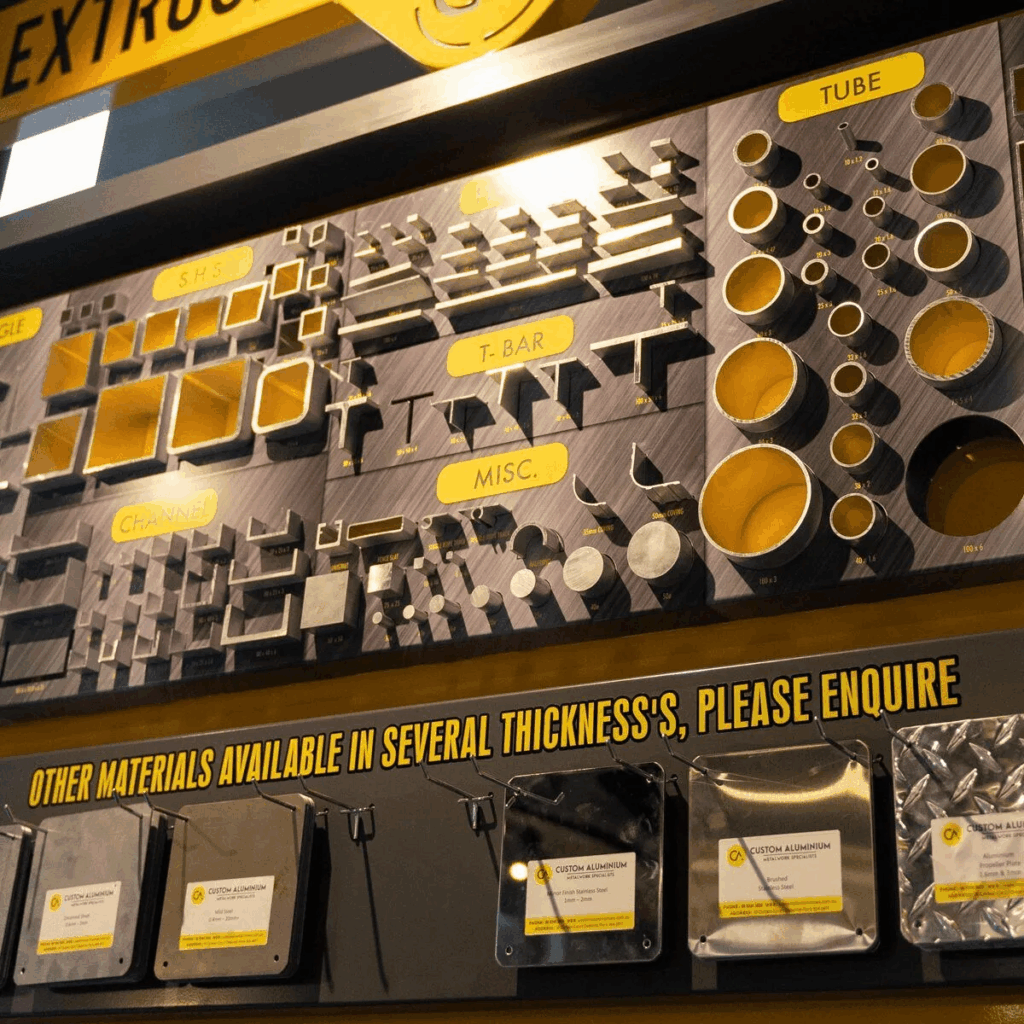

Aluminium is one of the most important and versatile materials in Australia’s industrial ecosystem. Known for its light weight, strength, corrosion resistance, and recyclability, it plays a critical role in multiple sectors ranging from construction to aerospace. Although Australia exports vast quantities of raw aluminium, it also consumes a significant amount domestically across a wide variety of applications.

Let’s break down the Australian industries that rely heavily on aluminium and explore how this adaptable metal contributes to their operations.

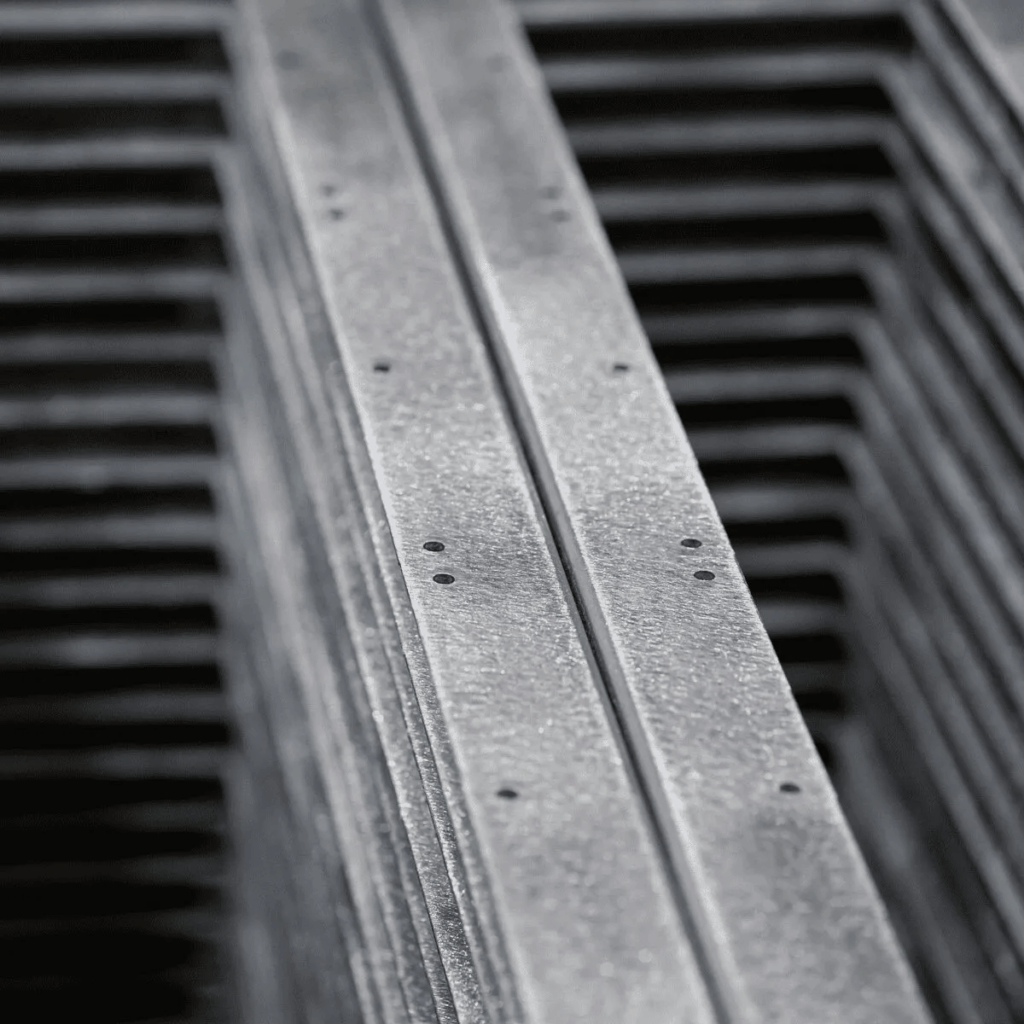

Construction and Infrastructure

Construction is by far one of the biggest consumers of aluminium in Australia. It’s easy to see why. The material is durable, lightweight, low-maintenance, and aesthetically versatile—all qualities prized by builders and architects.

Aluminium is commonly used in:

- Window and door frames: It doesn’t rust, needs little upkeep, and can be powder-coated in a wide variety of colours.

- Roofing, gutters, and downpipes: Lightweight and easy to install, aluminium performs well even in harsh Australian climates.

- Exterior cladding and facades: Modern buildings often feature aluminium for its sleek appearance and weather resistance.

- Framing and structural supports: While steel is often used for heavy-duty framing, aluminium is ideal for lighter structures where corrosion is a concern.

Aluminium is also valued in the push towards green construction. Its high recyclability means less waste and a smaller environmental footprint.

Transport and Automotive

The transport sector—road, rail, air, and sea—depends heavily on aluminium for performance, safety, and efficiency. In the auto industry, aluminium helps reduce the weight of vehicles, which improves fuel economy and lowers emissions.

Some key uses include:

- Car components: Engine parts, gearboxes, radiators, and body panels.

- Truck and trailer panels: Lightweight panels reduce wear and tear on the engine and tyres.

- Rail carriages: Aluminium is used for floor and wall panels, significantly lowering the weight of train carriages and increasing fuel efficiency.

- Aircraft frames and interiors: Strong but light, aluminium is essential in reducing fuel usage for airlines.

- Bus frames: Buses benefit from aluminium frames and panels to meet safety standards without excessive weight.

Australia’s large geographic spread and high freight demands mean that transport efficiency is crucial—and aluminium delivers exactly that.

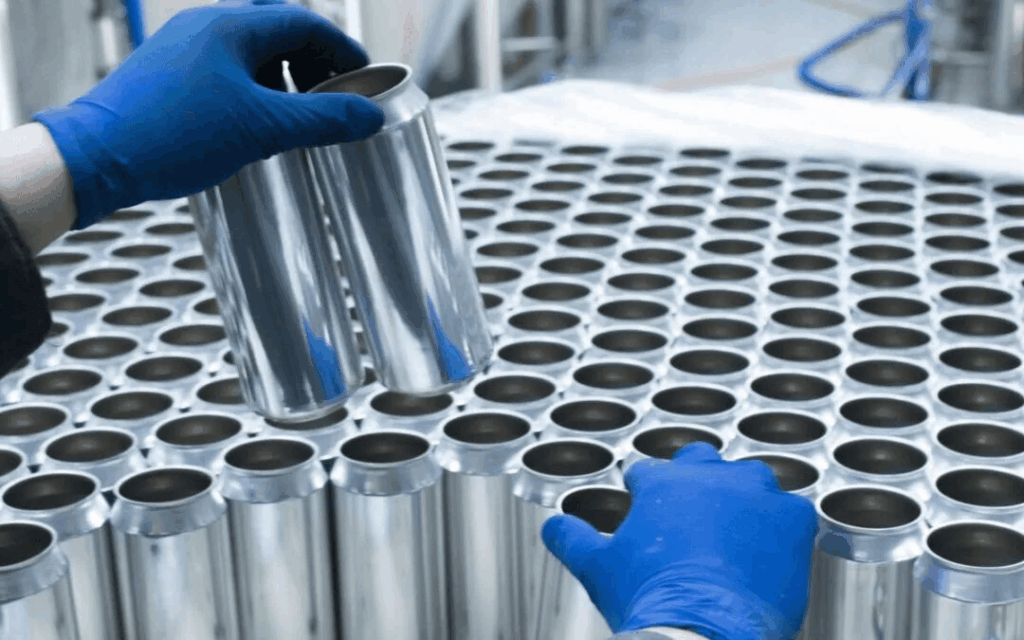

Packaging

In the packaging industry, aluminium shines—literally and figuratively. Its ability to protect contents from moisture, light, and air makes it the go-to material for food and beverage containers.

Popular aluminium packaging includes:

- Cans: Beverage cans are made from aluminium because they’re lightweight, don’t rust, and are infinitely recyclable.

- Foil: Perfect for wrapping food due to its flexibility and excellent barrier properties.

- Trays and containers: Lightweight aluminium trays are widely used in the food service industry, especially for takeaway and ready-made meals.

The circular economy benefits here are strong. Aluminium packaging can be remelted and reused endlessly without degrading in quality, making it an environmentally smart option for companies looking to reduce waste.

Electrical and Electronics

Aluminium is a staple material in the electrical sector due to its conductivity, cost-effectiveness, and corrosion resistance. While copper is still widely used, aluminium provides a lighter and cheaper alternative for many applications.

Some major uses include:

- Overhead power lines: Aluminium wiring is used in power transmission because it’s lighter and easier to work with at scale.

- Electrical busbars and connectors: These are essential components in industrial switchboards and substations.

- Heat sinks and housings: In electronics, aluminium is ideal for managing heat in devices like computers, TVs, and lighting.

- Solar panel frames: Aluminium offers strength without adding unnecessary weight, making it a key material in renewable energy installations.

As Australia expands its renewable energy infrastructure, demand for aluminium components in battery storage and solar installations is also growing.

Marine and Shipbuilding

Australia’s strong maritime industry also leans heavily on aluminium—particularly in the shipbuilding and recreational boating sectors. Its resistance to saltwater corrosion makes it a reliable option in a coastal country with a booming boating culture.

Typical marine uses:

- Boat hulls and frames: Lightweight hulls help improve speed and fuel efficiency.

- Superstructures and decking: Aluminium reduces top-heaviness and boosts vessel stability.

- Naval vessels and patrol boats: These benefit from aluminium’s strength, corrosion resistance, and ease of maintenance.

Because of its lightness and durability, aluminium helps reduce maintenance downtime and repair costs in marine applications—essential in both commercial and recreational sectors.

Defence and Aerospace

Few materials meet the strict requirements of military and aerospace applications like aluminium does. Its strength-to-weight ratio and resistance to corrosion make it indispensable in advanced engineering fields.

Some specific applications:

- Armoured vehicle components: Aluminium provides a lightweight option that doesn’t compromise durability.

- Aircraft parts: From wings to fuselage panels, aluminium is everywhere in aviation.

- Satellite structures and defence equipment: Precision aluminium components are vital for long-term reliability in space and defence tech.

Australia’s growing investment in defence infrastructure and local aerospace manufacturing ensures that aluminium will remain a strategic resource for years to come.

Renewable Energy

As Australia moves toward decarbonisation, aluminium is a quiet hero in the energy transition. Renewable energy systems often rely on aluminium for their physical infrastructure.

Notable uses:

- Solar mounting systems: Lightweight, corrosion-resistant aluminium mounts are essential for rooftop and large-scale solar arrays.

- Wind turbine components: Internal parts like cooling systems and housing enclosures make use of aluminium.

- Battery casings and frames: With energy storage becoming increasingly critical, aluminium’s thermal management capabilities are being put to good use.

As households and companies adopt greener energy solutions, aluminium is right there supporting the shift.

Final Thoughts

Aluminium is more than just a building material—it’s a backbone of modern industry in Australia. It’s trusted across sectors for its reliability, strength, and environmental benefits. Whether you’re driving on roads, flying across states, building a home, or farming in the outback, chances are aluminium is playing a quiet but crucial role in making it all possible.

As technology and sustainability become more central to Australia’s growth, aluminium is set to become even more vital in shaping the future of the country’s industrial landscape.