When discussing sustainability in modern construction and manufacturing, the focus frequently shifts towards eco-friendly materials. One such material that often finds itself at the centre of this conversation is aluminium.

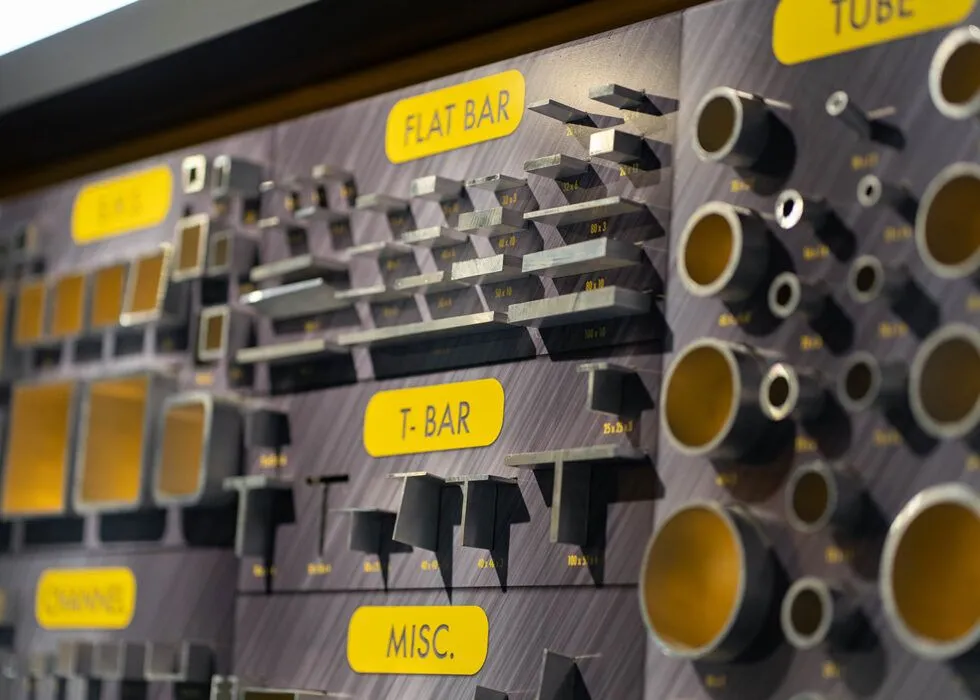

Known for its versatility, durability, and lightweight nature, aluminium has become a staple in industries ranging from construction to automotive. However, the question remains: are aluminium extrusions eco-friendly?

The Aluminium Extrusion Process and Environmental Concerns

The extrusion process itself involves several steps that raise environmental questions. First, aluminium must be mined, typically from bauxite ore. The extraction of bauxite and the refining process require significant amounts of energy. From there, the aluminium is melted and forced through a die to create the extrusions.

While the mining and refining processes are energy-intensive, the aluminium extrusion process does have some significant environmental advantages that help offset the initial energy consumption. One key benefit is that aluminium is infinitely recyclable, meaning it can be reused countless times without losing its properties. This recyclability plays a crucial role in reducing the overall carbon footprint of aluminium products.

Recyclability: A Key Benefit

One of the strongest arguments in favour of aluminium extrusions being eco-friendly is the recyclability of aluminium. Unlike many other materials, aluminium can be recycled indefinitely without degrading in quality. In fact, 75% of all aluminium ever produced is still in use today. Recycling aluminium uses only 5% of the energy required to produce new aluminium from bauxite. This drastic reduction in energy consumption significantly reduces the overall environmental impact of aluminium extrusions.

Recycled aluminium is often referred to as secondary aluminium, and it is just as strong and durable as its primary counterpart. When aluminium extrusions are created from recycled aluminium, the process is not only eco-friendly but also highly cost-effective. Industries that rely on aluminium extrusions can, therefore, benefit both economically and environmentally by opting for recycled aluminium.

Energy Efficiency in the Aluminium Extrusion Process

While the initial production of aluminium from bauxite requires a significant amount of energy, the aluminium extrusion process itself is relatively energy-efficient. Modern extrusion plants have adopted advanced technologies that allow them to use less energy while maintaining high levels of precision and output. Moreover, many plants are incorporating renewable energy sources, such as solar or wind power, to further reduce their carbon footprint.

Longevity and Durability

Another reason why aluminium extrusions are considered eco-friendly is their longevity. Aluminium is highly resistant to corrosion, which means that products made from aluminium extrusions can last for decades with little to no maintenance. In construction, for example, using aluminium extrusions for window and door frames ensures that these components remain structurally sound and aesthetically pleasing for many years.

The durability of aluminium reduces the need for frequent replacements, which in turn reduces the demand for new materials and energy consumption. In essence, the longevity of aluminium extrusions contributes to a circular economy, where materials are used for as long as possible before being recycled and reintroduced into the production cycle.

Lightweight Nature and Transportation Benefits

One often overlooked benefit of aluminium extrusions is their lightweight nature. Aluminium is about one-third the weight of steel, yet it offers comparable strength. This makes it an ideal material for applications where weight is a concern, such as in the automotive and aerospace industries.

The lightweight nature of aluminium extrusions also has environmental advantages. For instance, vehicles made with aluminium parts are lighter, which means they require less fuel to operate. This results in lower emissions and a reduced carbon footprint over the vehicle’s lifetime. Similarly, transporting aluminium extrusions requires less energy compared to heavier materials, contributing to reduced transportation emissions.

Sustainable Applications in Construction

The construction industry is increasingly turning to aluminium extrusions as a sustainable alternative to traditional materials. One of the primary reasons for this shift is the versatility of aluminium. It can be used for a wide range of applications, from structural components to decorative features. Additionally, the energy efficiency of buildings can be improved by using aluminium extrusions in window and door frames, as they provide excellent insulation properties.

Reducing Waste in the Manufacturing Process

Another significant advantage of using aluminium extrusions is the ability to reduce waste during the manufacturing process. The extrusion process allows for precise control over the shape and size of the final product, which means that manufacturers can produce exactly what is needed without excess material.

Moreover, any leftover aluminium from the extrusion process can be recycled and reused. This closed-loop system minimises waste and ensures that resources are used efficiently. In an industry where reducing waste is paramount to achieving sustainability goals, aluminium extrusions offer a clear advantage over other materials that may not be as easy to recycle or repurpose.

Conclusion: A Step Towards a Greener Future

Aluminium extrusions offer a range of eco-friendly benefits, from their recyclability to their durability and energy efficiency. While the initial production of aluminium is energy-intensive, the widespread use of recycled aluminium and advancements in manufacturing technologies have significantly reduced the environmental impact of aluminium extrusions.